Digitalization: a faster pace for new vaccine development and manufacturing

11 May 2021 | Tuesday | News

In short, turning to digitalization helps speed things up at GSK. In collaboration with Siemens, the company aims to create and introduce digital twins of the entire vaccine manufacturing process for all new vaccines. In other words, the digital twins of the product, production, and performance, which will all be linked together. The next step on the digitalization journey in the framework of the current project: development of digital twins for the following part-processes.

Global healthcare company GSK is collaborating with digitalization expert Siemens and digital transformation leader ATOS to digitalize its vaccine development and production process. A key benefit will be much shorter development times for vaccines, allowing them to reach people faster and with the optimum quality. The digital twin plays a big role.

Right now, vaccine development typically progresses in many small silos, each digitalized to some extent in its own environment, but with few connections between them. This is where there is potential for optimization. Being able to consider the process as a whole and digitalizing the entire value chain would represent a significant improvement.

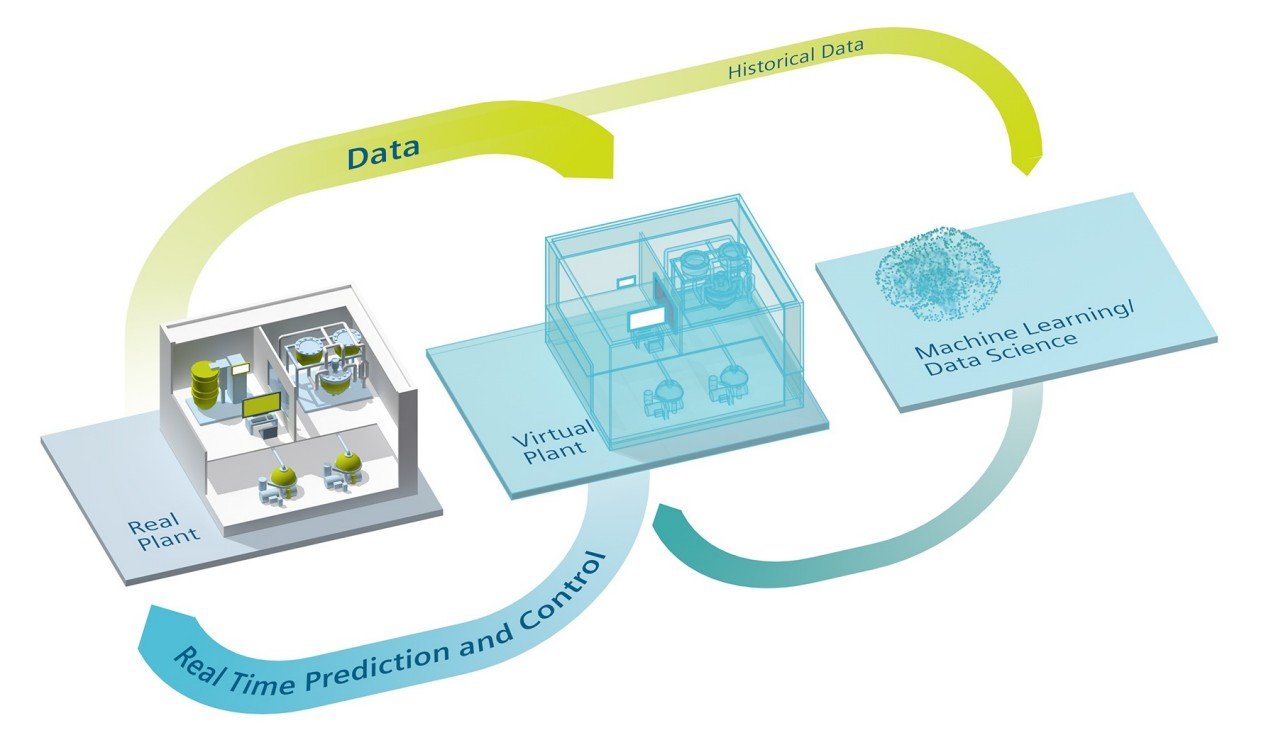

Digital twin: the virtual and real worlds in a closed loop

For this, Siemens offers an innovative portfolio of Digital Enterprise solutions – it covers product design, which is here developing the vaccine and making the active ingredient, otherwise referred to as primary processing, and manufacturing the pharmaceutical itself, or secondary processing. Siemens collaborated with GSK and ATOS to develop an innovative concept named digital twin, which combines the virtual and real worlds in a closed loop.

"Getting vaccines faster to patients" - GSK, Siemens and ATOS digitalization collaboration (recording from Digital Enterprise Virtual Experience, April 2021)

Most Read

- Innovations In Magnetic Resonance Imaging Introduced By United Imaging

- Management of Relapsed/Refractory Multiple Myeloma

- 2025 Drug Approvals, Decoded: What Every Biopharma Leader Needs to Know

- BioPharma Manufacturing Resilience: Lessons From Capacity Expansion and Supply Chain Resets from 2025

- APAC Biopharma Review 2025: Innovation, Investment, and Influence on the Global Stage

- Top 25 Biotech Innovations Redefining Health And Planet In 2025

- How Health Systems Are Reshaping Drug Adoption, Partner Models, and Market Access in 2026

- The New AI Gold Rush: Western Pharma’s Billion-Dollar Bet on Chinese Biotech

- Single-Use Systems Are Rewiring Biopharma Manufacturing

- The State of Biotech and Life Science Jobs in Asia Pacific – 2025

- Asia-Pacific Leads the Charge: Latest Global BioSupplier Technologies of 2025

- Invisible Threats, Visible Risks: How the Nitrosamine Crisis Reshaped Asia’s Pharmaceutical Quality Landscape

Bio Jobs

- Sanofi Turns The Page As Belén Garijo Steps In And Paul Hudson Steps Out

- Global Survey Reveals Nearly 40% of Employees Facing Fertility Challenges Consider Leaving Their Jobs

- BioMed X and AbbVie Begin Global Search for Bold Neuroscience Talent To Decode the Biology of Anhedonia

- Thermo Fisher Expands Bengaluru R&D Centre to Advance Antibody Innovation and Strengthen India’s Life Sciences Ecosystem

- Accord Plasma (Intas Group) Acquires Prothya Biosolutions to Expand Global Plasma Capabilities

- ACG Announces $200 Million Investment to Establish First U.S. Capsule Manufacturing Facility in Atlanta

- AstraZeneca Invests $4.5 Billion to Build Advanced Manufacturing Facility in Virginia, Expanding U.S. Medicine Production

News