NUS Researchers Harness AI and 3D Bioprinting to Personalise Gum Tissue Grafts

07 April 2025 | Monday | News

Image Source : Public Domain

AI-enabled workflow streamlines oral soft tissue fabrication, paving the way for personalised, less invasive dental treatments

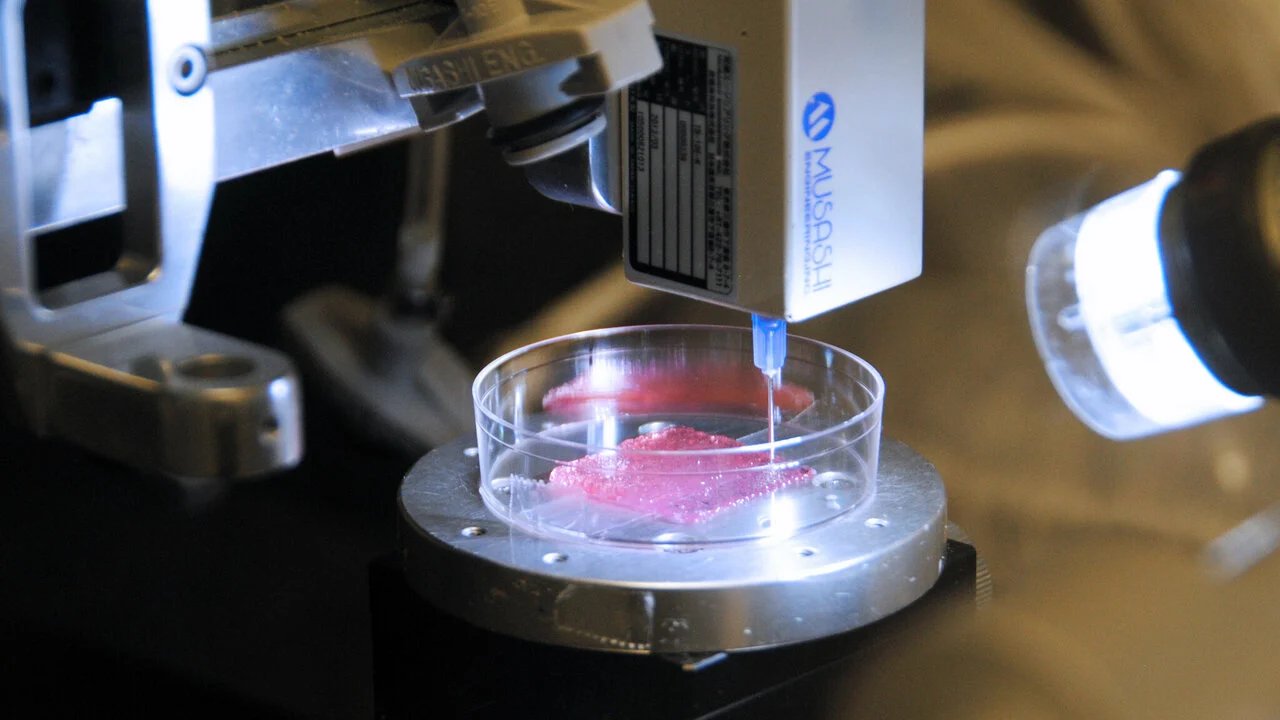

A team of researchers from the National University of Singapore (NUS) has unveiled a transformative approach to regenerative dental care, combining artificial intelligence (AI) and 3D bioprinting to create personalised gingival (gum) tissue grafts. This breakthrough significantly reduces the time, cost, and resource burden of traditional dental grafting, while enhancing precision and patient comfort.

Led by Assistant Professor Gopu Sriram from the NUS Faculty of Dentistry, the research presents a game-changing alternative to conventional grafting methods, which typically involve painful and invasive harvesting of tissue from the patient’s mouth.

Published in Advanced Healthcare Materials on December 17, 2024, the study was supported by grants from the National Additive Manufacturing Innovation Cluster (NAMIC) and National University Health System (NUHS).

“This research demonstrates how AI and 3D bioprinting can converge to solve complex medical problems through precision medicine,” said Asst Prof Sriram. “By optimising tissue grafts for individual patients, we can reduce the invasiveness of dental procedures while ensuring better healing and recovery.”

AI-Driven Bioprinting: A New Frontier in Regenerative Dentistry

Gum grafting is vital for treating mucogingival defects like recession or damage due to periodontal disease and implants. However, current practices rely on donor tissue from the patient’s palate, which is limited and often leads to discomfort and complications.

To address these limitations, the NUS team developed a bio-ink that maintains structure and cell viability, then integrated AI to optimise bioprinting parameters — such as extrusion pressure, nozzle size, and temperature — reducing the typical thousands of test combinations to just 25.

“This AI-guided method greatly accelerates parameter optimisation in bioprinting,” said Professor Dean Ho, Head of Biomedical Engineering at NUS and co-corresponding author. “It not only enhances the efficiency of biofabrication but ensures consistent, high-quality outcomes tailored to each patient.”

The printed gum tissue grafts retained over 90% cell viability and exhibited biomimetic structure, mimicking natural gum with key proteins and a multilayered architecture. These features point to real-world clinical potential.

Beyond Dentistry: A Model for Future Tissue Engineering

The scarless healing properties of oral tissue provide a unique advantage, with the potential to inspire similar grafts for skin and other barrier tissues. Co-investigator Dr Jacob Chew, a periodontist and Academic Fellow at NUS Faculty of Dentistry, noted that personalised grafts minimise tension and distortion, potentially shortening surgery time and reducing post-operative complications.

Next Steps: From Lab to Clinic

The team’s next phase includes in vivo studies to evaluate how well the grafts integrate in oral environments and exploring multi-material bioprinting to incorporate vascular structures — a leap forward toward more functional and complex tissue grafts.

Most Read

- How Does GLP-1 Work?

- Innovations In Magnetic Resonance Imaging Introduced By United Imaging

- Management of Relapsed/Refractory Multiple Myeloma

- 2025 Drug Approvals, Decoded: What Every Biopharma Leader Needs to Know

- BioPharma Manufacturing Resilience: Lessons From Capacity Expansion and Supply Chain Resets from 2025

- APAC Biopharma Review 2025: Innovation, Investment, and Influence on the Global Stage

- Top 25 Biotech Innovations Redefining Health And Planet In 2025

- The New AI Gold Rush: Western Pharma’s Billion-Dollar Bet on Chinese Biotech

- Single-Use Systems Are Rewiring Biopharma Manufacturing

- The State of Biotech and Life Science Jobs in Asia Pacific – 2025

- Asia-Pacific Leads the Charge: Latest Global BioSupplier Technologies of 2025

- Invisible Threats, Visible Risks: How the Nitrosamine Crisis Reshaped Asia’s Pharmaceutical Quality Landscape

Bio Jobs

- Sanofi Turns The Page As Belén Garijo Steps In And Paul Hudson Steps Out

- Global Survey Reveals Nearly 40% of Employees Facing Fertility Challenges Consider Leaving Their Jobs

- BioMed X and AbbVie Begin Global Search for Bold Neuroscience Talent To Decode the Biology of Anhedonia

- Thermo Fisher Expands Bengaluru R&D Centre to Advance Antibody Innovation and Strengthen India’s Life Sciences Ecosystem

- Accord Plasma (Intas Group) Acquires Prothya Biosolutions to Expand Global Plasma Capabilities

- ACG Announces $200 Million Investment to Establish First U.S. Capsule Manufacturing Facility in Atlanta

- AstraZeneca Invests $4.5 Billion to Build Advanced Manufacturing Facility in Virginia, Expanding U.S. Medicine Production

News